Silicone is a material that can be used in a wide range of residential and industrial applications. It is a solid, flexible polymer that can be shaped into various shapes. The versatility of silicone is quite appealing since it provides access to materials with extremely high wear and temperature tolerances. The crucial question at hand is: Is silicone heat resistant?

Although the topic of silicone’s heat resistance is vast, the common consensus is that it usually is. While certain silicones have a high heat resistance, some do not. Silicone products ‘ heat resistance varies greatly depending on how they will be used.

Silicone products, such as cookware, automotive parts, industrial gaskets, sealants, rubber sheets, and insulators, must be the most heat resistant. Their tolerance criteria vary, making it difficult for the typical consumer to determine which is best for their particular needs.

Structure of Silicone

Let us quickly review what silicone is before getting into its heat-resistant qualities. Contrary to silicon, silicone is a synthetic, artificially made elastic polymer with excellent flexibility, wear resistance, and durability. Physically, it is far more advanced than elastomers found in nature.

Conversely, silicon is a naturally occurring substance with a shiny sheen that is typically brittle. Silicone is available in almost all hardware stores. Conversely, silicon is significantly scarcer. However, the memory chip in your computer or phone has some.

Silicon is the main component of silicone polymers, despite having remarkably dissimilar physical properties. Although the precise material makeup of industrial silicone varies, siloxane, oxygen, carbon, and hydrogen are typically present in some amount. This movie provides a thorough and comprehensive explanation of the chemical structure of silicone.

Silicone’s Temperature Threshold and Variations

Due to its low compression set, heat resistance, and electrical conductivity (dielectric strength), silicone is a widely used industrial material. The nicest thing about silicone, though, is that it stays hot. It can withstand a wide range of temperatures while maintaining its chemical composition and structural integrity thanks to its high thermal stability.

The temperature range in which the majority of industrial-grade silicone can function is -100°C to 300°C. There are very few materials that can match that enormous effective threshold. Because siloxane has a chemical structure that is resistant to changes brought on by heat, it is the main component that gives silicone its great thermal stability.

The specs of consumer-grade silicone are marginally lower than those of its industrial equivalents. It can withstand temperatures between -60°C and 250°C well. Even yet, these are still quite remarkable figures. Comparable materials with significantly less versatility include PVC, Latex, and Vinyl.

PVC, Latex, and Vinyl all have much lower temperature resistance while offering similar or inferior durability. Some of these materials are highly toxic, while most silicones are entirely inert and safe.

Different Types of Silicone

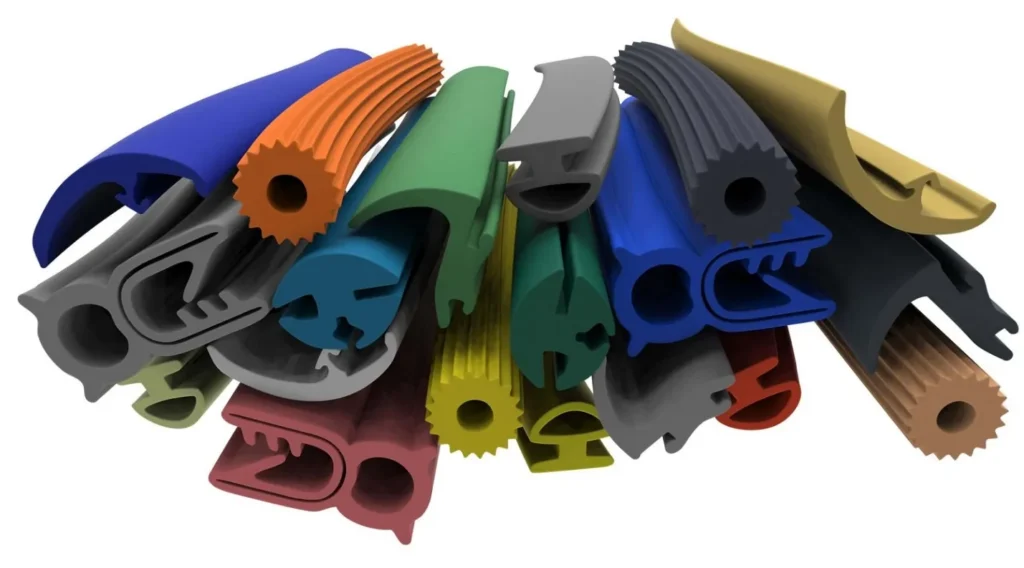

Numerous silicone specimens are available for consumer use, however they typically fit within a small number of categories. Although silicone items within the same category may vary in a few distinct ways, this variance is not as great as what you would see within other categories.

Here are some of the most common Silicone variants:

1. RTV Silicone

Room Temperature Vulcanizing is referred to as RTV. This kind of silicone is typically offered as a liquid, and at room temperature, it solidifies into a flexible rubber. This kind of silicone is probably what sealants contain.

Because of its superior insulating qualities, this type of silicone is also used to make gaskets, insulation sheets, and other items of a similar nature. RTV silicone is still most frequently used in insulation sealants, though. RTV is present in almost all kitchen and bathroom insulating liquid sealants.

RTV silicone goods can be broadly divided into three categories: liquid sealants, insulation sheets, and appliance components. Additionally, RTV silicone is used to create premium adhesives. The cost of RTV silicone is the sole drawback, as it is much more expensive than other silicone compounds for non-industrial use.

2. Fluorosilicone Rubber

Solid silicones with high wear resistance and good flexibility are known as fluorosilicone rubber. Fluorosilicone rubber is typically sold in sheets, sponges, or various molded shapes.

In the home, silicone foam and sheets like these are frequently used as insulation cushions. In the industrial sector, the largest consumers of fluoro silicone are the automotive and aerospace sectors. Fluorosilicone wires, pipes, and insulation covers are also commonly used.

3. LSR Silicone

Liquid silicone rubber is referred to as LSR silicone. Contrary to what the name implies, this kind of silicone is not the main kind present in liquid sealants. Rather, LSR is mostly utilized in the production of industrial and household goods including automotive parts and medical equipment.

LSR is a great material for food-grade containers and surgical components since it is flexible, easy to form, and fully inert when it comes into contact with other chemicals. Although liquid silicone requires a difficult curing procedure, extrusion and even 3D printing make shaping it very simple.

4. HCR Silicone

The final one is Heat-Cured Rubber or HCR. HCR is a common material for applications requiring a lot of heat. By default, these silicone materials have extreme fire resistance.

Their non-toxic and non-corrosive qualities make them an excellent option for commercial and residential applications. Additionally, due to their limited thermal conductivity, these silicone sheets do not permit temperature to pass through them.

Such silicone sheets are frequently used in hospitals and other locations requiring hygienic conditions. Watch this video to learn more about how HCR silicone is made.

What is heat resistant silicone?

Heat-resistant silicone is a powerful and long-lasting glue. It can withstand temperatures up to 300°C without degrading or damaging, and certain varieties can withstand flame exposure. Thus, heat-resistant silicone is the perfect material to use near fires or in other high-temperature areas.

Heat-resistant silicone is resilient to high temperatures and deters deterioration over time. It is a flexible substance resistant to moisture and chemicals, implying that it will endure over time in even the most taxing settings.

What is heat resistant silicone used for?

Heat-resistant silicone is frequently employed in automotive applications because it can tolerate the heat of a hot engine. Axle housings, solenoid covers, water and oil pump seals, and valve covers are just a few of its applications. High-temperature sealants provide exceptional resistance in regions where the joint or connection is exposed to heat.

Industrial gaskets and heavy machinery also employ heat-resistant silicone. Boilers, stoves, ductwork, and ovens are among the other uses. An example of a high-temperature sealant is silicone, which has been a fire retardant. Its purpose is to prevent the spread of harmful gasses, smoke, and fire.

Applications of silicone due to its melting point

- To prevent damage from moisture, silicone is used in the construction of residential buildings.

- To withstand sun for years, increase durability and efficiency, silicone is used in solar cells.

- Key band, keyboard and components of computers and mobile phones make use of silicone due to its thermal stability.

- Silicone is used as adhesives and sealants to protect the parts of the airplane.

- Modern bakewares and cookware are made using silicone.

- Silicone is an excellent lubricant used in airsoft gun parts and bicycle chains.

How to pick the best silicone that resists heat for your needs

You must take into account the temperature range that the silicone must tolerate in addition to the desired degree of flexibility and durability when selecting a heat-resistant silicone. Knowing a little bit about the various kinds of silicone and its characteristics will help you make an informed choice that will work for you.

For example, you may choose heat-resistant silicone rather than caulk because silicone is more pliable and suitable for joints and moving parts. Just make sure the product is marked as high temperature silicone or heat resistant silicone. High temperatures will not be tolerated by regular sealants.

The advantages of silicone that resists heat

Heat resistant silicone has a number of advantages over other materials. The main ones are:

Heat-resistant silicone is also resistant to tearing, abrasion, and vibrations, making it an excellent choice for high-wear applications. Its high flexibility indicates that it is appropriate for expanding and contracting areas. Its resistance to high temperatures makes it an ideal choice for applications where temperature extremes are a concern, including automotive and aerospace applications.

Chemical resistance, Most solvents and cleansers will not harm heat-resistant silicone.

The material is strong and appropriate for outdoor use because it is resistant to moisture and UV radiation.

Why is silicone so heat resistant?

Another way to characterize silicone’s low thermal conductivity is to describe its good “thermal stability,” or the capacity to maintain structure and qualities across a wide temperature range. This means it transmits heat much more slowly than some other materials, resulting in superior heat resistance.

The material’s extremely stable chemical structure is significant in its heat resistance. Silloxane’s backbone is a stable structure that prevents the material from breaking down when heated. Given its exceptional qualities, silicone seems to have many uses and applications.

Conclusion

That concludes our brief guide to various types of silicone. Let’s go over the main points quickly: is silicone heat resistant? Yes, it is. But, different silicone products have different heat resistance thresholds. Thermal resistance and thermal stability make silicone one of the premier materials for many consumer and industrial products.

If you want to learn more about silicone and various silicone products, then feel free to contact us. We have been manufacturing high-quality, heat-resistant silicone for the past 36 years and do our best to use our expertise to help you.

For more information on what Silicone products, we can offer you, please click here or contact our expert Sales team!

Frequent Ask Questions

What is the unique nature of the melting point of silicone?

Though silicone doesn’t have any particular melting point, the temperature at which silicone loses its mechanical properties such as elasticity, that temperature is recorded as phase transition temperature.

Why does silicone have no particular melting point?

Due to extreme heat resistivity, silicone doesn’t show any reaction because it has a long chain arrangement of molecules. At higher temperatures, silicone will burn immediately. Thus, it has no proper melting point.